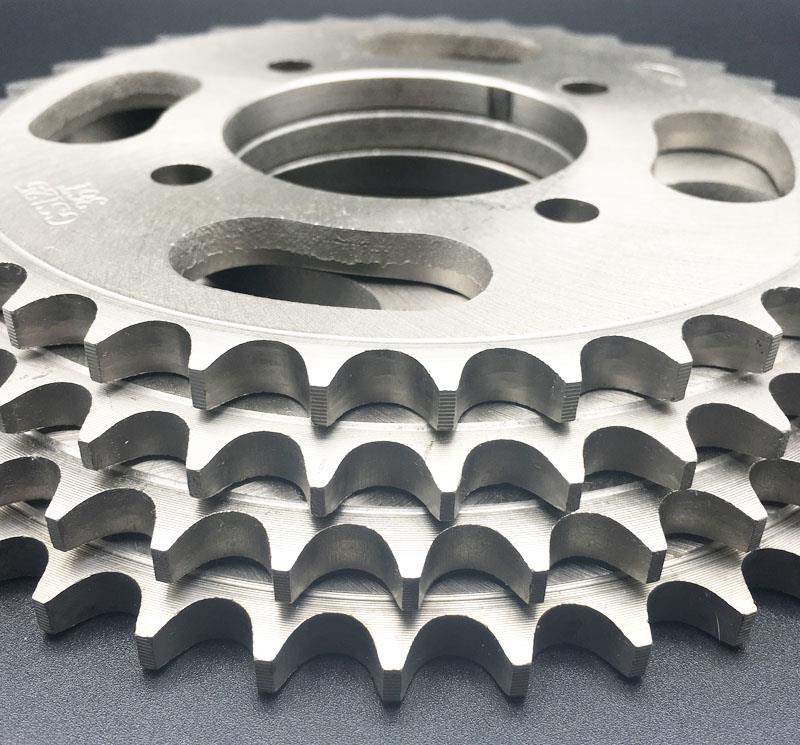

Custom Motorcycle Sprockets Manufacturer

Sprockets are one main product of MPM-motorsports for motorcycles and ATVs. MPM custom motorcycle sprockets are usually made from high-quality materials, such as high-quality steel or aluminum alloy, to ensure their durability and high performance. These sprockets can be customized according to customer requirements, including different numbers of teeth, different gear ratios, and different chain sizes to meet customer needs for acceleration performance, top speed, and fuel efficiency.

Custom Chains And Sprockets

Our Factory

We are a factory specializing in the design, manufacture, and wholesale of motorcycle sprockets. Over the years, we have been committed to providing high-quality, reliable, and affordable products to meet the needs of different types of motorcycle users.

Material:45#Steel/A3 Steel sprocket,20CrMnTi chain

Color: Natural/Black/Silver/According to your needs

Wholesalers can choose different custom motorcycle sprockets according to their needs to meet the needs of their customers. MPM can also provide customers with professional technical support and advice to ensure that the sprocket selected by the customer has the best fit and performance. MPM also provides quality assurance and after-sales service support to ensure that wholesalers are satisfied with the customized motorcycle sprocket. No worries.

World Leading Sprocket Manufacturer

MPM is the world’s leading sprockets manufacturer for motorcycles and ATVs.

High Quality Sprockets

Leading technologies in materials and technologies Produced to ensure maximum durability

Strong Production Capacity

We offer the ultimate in custom sprockets that are unmatched

-

KTM Aluminum Rear Sprocket 45T Duke390 for Motorcycle

-

KTM 450 38T 520 Rear Sprocket for ATV

-

KTM 1290 Superduke Rear Sprocket for Motorcycle

-

HONDA CB650 Rear Sprocket for Motorcycle

-

Honda CB500 Rear Sprocket for Motorcycle

-

SUZUKI SV650 Rear Sprocket for Motorcycle

-

SUZUKI GSXR600 Rear Sprocket for Motorcycle

-

KAWASAKI KX65 Rear Sprocket for Dirt Bike Motorcycle

-

HONDA CRF50 Rear Sprocket for Dirt Bike Motorcycle

-

SUZUKI DL650 Rear Sprocket for Motorcycle

-

HONDA CB125 Rear sprocket for Motorcycle

-

YAMAHA XJ6 Motorcycle Sprocket FZ6R 46T steel rear

-

Wholesales YAMAHA Motorcycle Sprocket 428 43t for YBR125 Z125

-

Hyosung GT250 Motorcycle Sprocket 46T Rear Steel

-

YAMAHA 43t Rear Motorcycle Sprocket for WR250R

-

xv250 sprocket rear 520 45T custom

Custom Motorcycle Sprocket Size Chart

MPM custom rear motorcycle sprockets

Custom 6061-grade or 7075- grade Aluminium sprockets for Street, Track, Drag, Sand Drag, Buggyand Stunt including extreme oversize up to 100 teeth.

Chain Pitch

- 520

- 525

- 530

- 420

- 428

- 415

Teeth

- custom

Style

- Blank

- Circle

- Harley

- MT

- KTM

- Custom Design, Additional charges apply, please contact us for a quote.

Anodizing

- None

- Black

- Any anodizing color

Custom motorcycle sprockets are the epitome of technical precision and stunning aesthetics. With their aluminum core, they strike the perfect balance between strength and lightweight design. These sprockets are engineered to enhance the system life of your motorcycle, ensuring durability and reliability on the road. Whether you’re a racer, an off-road adventurer, or a daily commuter, the wide range of customization options allows you to find the perfect fit for your bike. Upgrade your motorcycle with custom sprockets that not only deliver exceptional performance but also add a touch of style to your ride. Experience the power, longevity, and visual appeal that custom motorcycle sprockets bring to your two-wheeled companion.Custom motorcycle sprockets are the epitome of technical precision and stunning aesthetics. With their aluminum core, they strike the perfect balance between strength and lightweight design. These sprockets are engineered to enhance the system life of your motorcycle, ensuring durability and reliability on the road. Whether you’re a racer, an off-road adventurer, or a daily commuter, the wide range of customization options allows you to find the perfect fit for your bike. Upgrade your motorcycle with custom sprockets that not only deliver exceptional performance butCustom motorcycle sprockets are the epitome of technical precision and stunning aesthetics. With their aluminum core, they strike the perfect balance between strength and lightweight design. These sprockets are engineered to enhance the system life of your motorcycle, ensuring durability and reliability on the road.

MOQ :100 pcs/model

Delivery Time: 10 working days

Custom Motorcycle Sprockets

Customization options

- Dimensions

- Logo

- Package

The process of customizing

1.Determine requirements

Provide specific requirements for sprockets, including size, material, number of teeth, tooth shape, heat treatment requirements, etc.

2.Sign a contract

Both parties need to sign a customized contract to clarify product specifications, quality, price, delivery date and other terms.

3.Custom production

MPM carries out the design and manufacture of sprockets.

Quality inspection: After production is completed, quality inspection is carried out to ensure that the quality of the sprocket meets the requirements.

4.Delivery and after-sales

After passing the inspection, the sprocket will be delivered to the customer and corresponding after-sales service will be provided.

How to Properly Maintain Your Sprockets

Proper maintenance of your motorcycle sprockets can significantly extend their lifespan and improve your motorcycle’s performance.

- Keep your chain clean and lubricated to reduce wear on the sprockets.

- Check the alignment of your sprockets regularly to ensure they are properly aligned with the chain.

- Tighten the chain to the manufacturer’s recommended specifications to prevent excessive wear on the sprockets.

- Avoid riding your motorcycle in harsh conditions, such as mud or sand, as this can cause premature wear on the sprockets.

- Inspect your sprockets regularly for any signs of wear or damage.

Check the sprockets regularly for any signs of wear or damage.

By following the tips above, you can significantly extend the life of your sprockets.

FAQ About Customizing Motorcycle Sprockets

In general, a bigger rear sprocket on a motorcycle will not make it go faster. In fact, it usually has the opposite effect. A larger rear sprocket increases the gear ratio, which means the engine has to work harder to turn the wheel. This can result in slower acceleration and a lower top speed.

Conversely, a smaller rear sprocket will usually increase the motorcycle’s top speed, but it may reduce low-end torque and acceleration. The choice of sprocket size depends on the specific requirements of the rider and the type of riding they will be doing.

It’s important to note that changing the sprocket size will affect the overall performance of the motorcycle, and it’s recommended to consult with a motorcycle mechanic or expert before making any modifications.

Adding teeth to the rear sprocket of a motorcycle will increase the gear ratio. This means that for each revolution of the engine, the rear wheel will turn fewer times, resulting in a reduction in overall speed but an increase in torque.

In practical terms, adding teeth to the rear sprocket will generally improve low-end acceleration and pulling power. This can be beneficial for certain types of riding, such as off-road or stop-and-go city riding, where quick acceleration from a standstill is important. However, it may result in a lower top speed and potentially higher engine RPM at cruising speeds.

It’s important to consider the trade-offs when modifying the sprocket size, as it will have an impact on the overall performance and characteristics of the motorcycle. As always, it’s advisable to consult with a motorcycle mechanic or expert to ensure that any modifications are appropriate for the specific riding needs and the motorcycle’s capabilities.

Yes, if you install a larger rear sprocket on your motorcycle, you will likely need a longer chain. When you increase the size of the rear sprocket, the distance between the front and rear sprockets also increases. As a result, the original chain may not be long enough to accommodate the larger sprocket.

It’s important to ensure that the chain is the correct length and properly tensioned to avoid issues such as excessive slack, which can lead to poor performance and potential safety hazards. When making changes to the sprocket sizes, it’s recommended to consult with a motorcycle mechanic or expert to determine the appropriate chain length and make any necessary adjustments to ensure proper fit and performance.

The choice of material for motorcycle sprockets depends on various factors such as the intended use, budget, and desired performance characteristics. Some common materials used for motorcycle sprockets include:

1. Steel: Steel sprockets are durable, cost-effective, and suitable for a wide range of applications. They are known for their strength and resistance to wear, making them a popular choice for many motorcycles.

2. Aluminum: Aluminum sprockets are lighter than steel sprockets, which can contribute to reduced unsprung weight and improved handling. They are often used in high-performance applications where weight reduction is a priority.

3. Titanium: Titanium sprockets are extremely lightweight and offer high strength, making them ideal for racing and high-performance motorcycles. However, they are also more expensive than steel or aluminum sprockets.

4. Composite materials: Some sprockets are made from composite materials, which can offer a good balance of strength, weight, and cost. These materials may include reinforced plastics or carbon fiber.

The best material for motorcycle sprockets ultimately depends on the specific requirements of the rider, the type of riding, and the desired trade-offs between weight, durability, and cost. It’s important to consider factors such as the intended application, maintenance requirements, and budget when selecting the most suitable material for motorcycle sprockets.

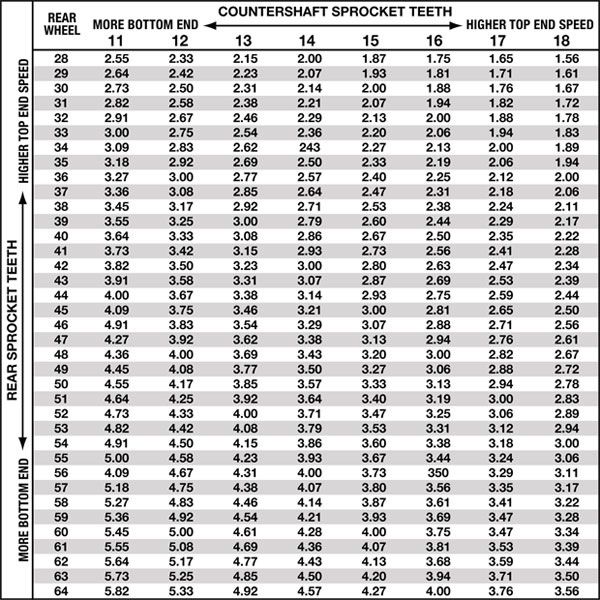

Details can be viewed from the sprocket specialists catalog below.

Send An Enquire

Changing the number of teeth on the sprockets may also require adjusting the chain length or the position of the rear wheel. Chain length can be calculated based on the chain pitch, with each chain link typically requiring around 16mm of length. For example, removing one tooth from the rear sprocket would make the chain looser, requiring the rear wheel to be moved backward by approximately 5mm to maintain proper tension. It’s important to remember that due to chain construction, even numbers of links need to be removed when adjusting chain length (2, 4, 6, 8, etc.).