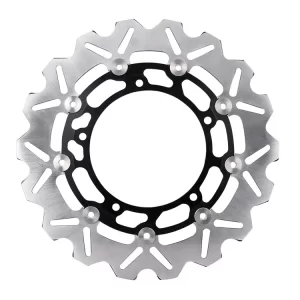

Motorcycle Brake Rotor

Looking for wholesale and custom motorbike brake discs? We supply high-quality brake discs for wholesalers, with customization options available. Enhance your business by providing reliable and tailored motorbike brake discs. Understand disc brake principles and maintenance for optimal performance. Partner with us for a wide range of wholesale and custom options. Contact us now to discuss your needs. wholesale and custom motorbike brake discs? We supply high-quality brake discs for wholesalers, with customization options available.

- Exceptional quality and unique designs

- Wide range of brake discs for almost all applications

- High-quality materials used in production

- Tightest tolerance and precise surface grinding techniques employed

- Perfectly true running with reduced vibration

Improved adaptation of brake pads - Absolute reliability and top performance without compromise

- Ultra-hardened surface for extended service life and dimensional stability

- Street legal discs come with a type approval, meeting regulatory standards

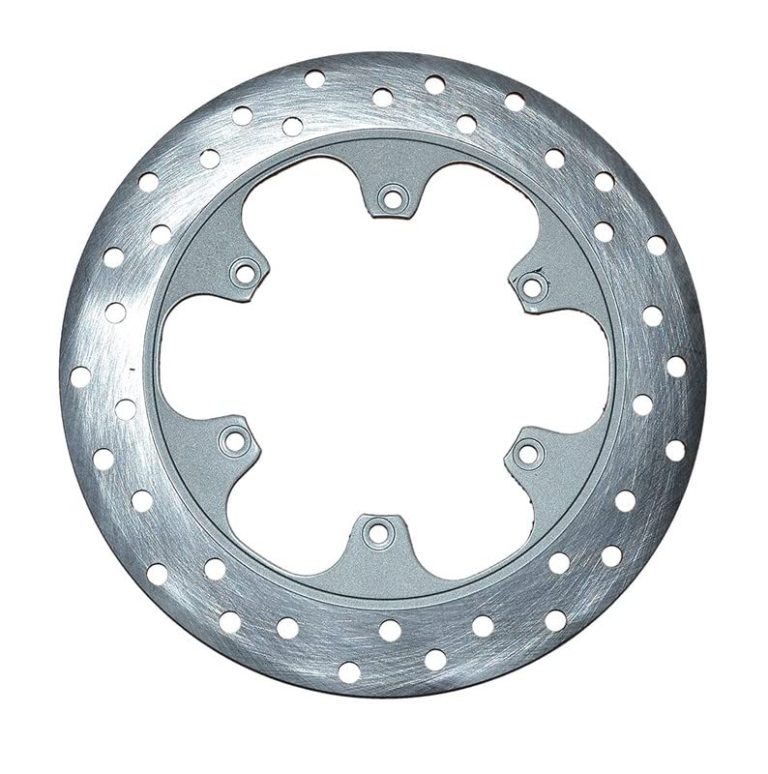

Solid &Fixed Rotor

These are the most common type of rotor and are typically made from a single piece of cast iron. They are simple, durable, and cost-effective

Floating Rotor

These rotors are made up of two separate pieces – the rotor and the carrier. The carrier is connected to the wheel hub, while the rotor is free to move around the carrier. This design helps to reduce heat transfer to the wheel hub and improve braking performance.

Wave rotors

These rotors have a wavy or contoured edge that helps to improve cooling and reduce weight. They are popular in racing applications where weight savings and high-performance braking are important.

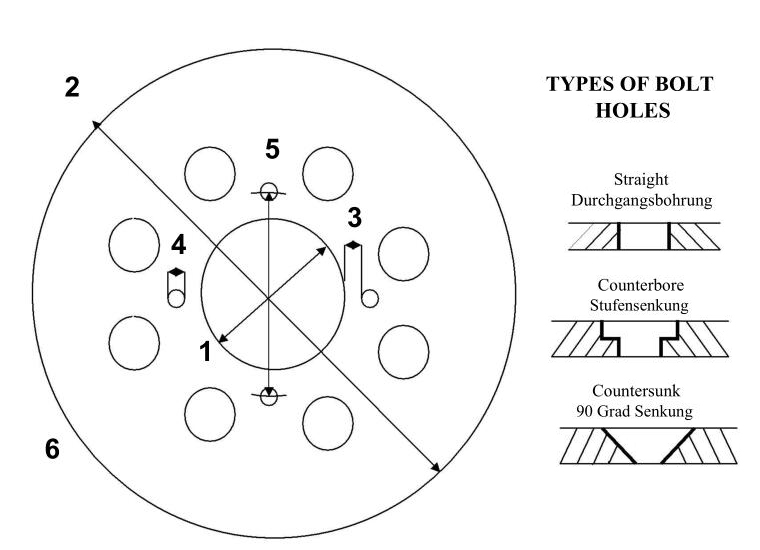

How To Measure Our Brake Discs Rotor

Instructions for measuring a brake disc

- ID = Inside Diameter (mm): measure from inside edge to inside edge.

- OD = Outside Diameter (mm): measure from outside edge to outside edge.

- Measurement from inside edge of mounting hole to inside edge of bolt hole (mm).

- Diameter = The bolt hole diameter: measure from inside bolt hole edge opposite inside bolt hole edge (mm).

- BHC = Bolt Hole Circle (mm): To measure this, use the following equation = 1 x Measurement 1 + 2 x Measurement 3 + 1 x Measurement 4 = BHC.

- Thickness (mm): Stand the disc vertically, and measure the thickness of the edge from outside wall to outside wall.

Why Choose Our Brake Discs

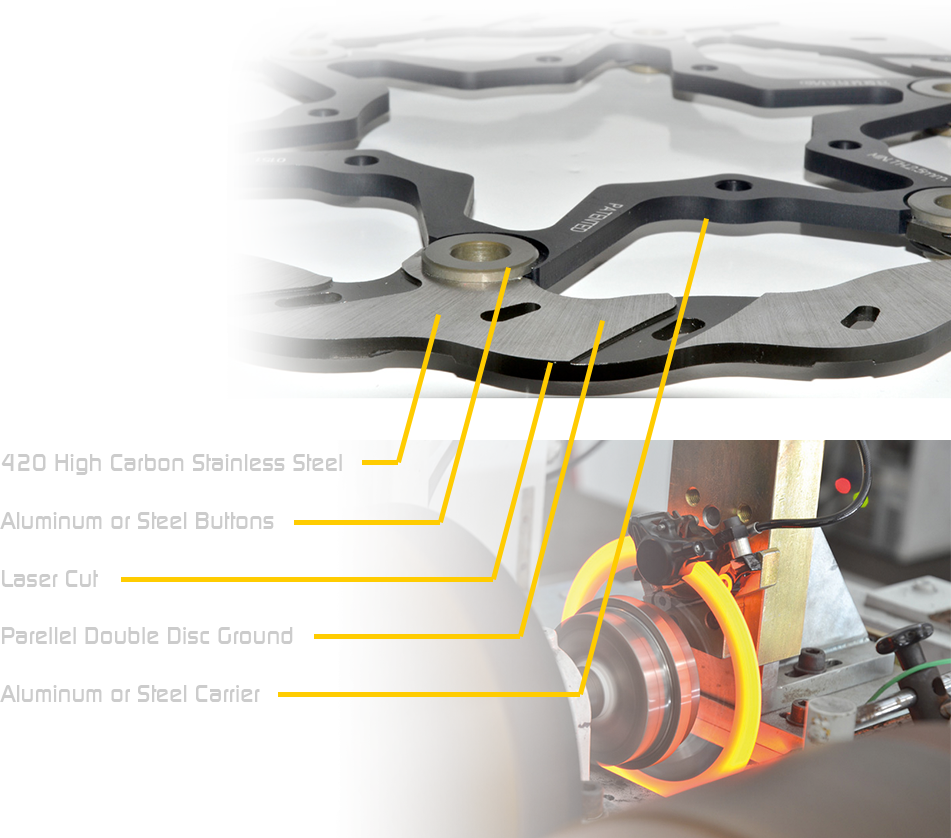

Raw Materials

Our products are made using the best available materials.

Aviation-grade 6061-T6/7075 aluminum alloy for lightweight competition floating brake disc inner line.

the outer line of the floating rotor or fixed brake rotor is stainless steel 420 (2Cr13)

ODM Design

Over the past decade, we have witnessed a plethora of styles and varieties in design on motorcycle brake rotors. Our designers have been able to create their own unique designs based on your specific needs. Additionally, we can also make necessary modifications in accordance with popular styles in the market to adapt to its evolving trends.

Production

The essence of a high quality products is in the high precision of manufacturing and the inherent quality of the material. Through accurate machining, ensures products maximum durability and performance.

Surface Treatment

Heat treated and anodized finished to perfection, all products meet or exceed the highest possible quality standards set for the motorcycle industry.

Quality Control

Implementing strict process controls involves creating SOPs, providing training, calibrating equipment, monitoring critical parameters, conducting inspections, analyzing data, and fostering continuous improvement. These measures ensure consistency, adherence to quality standards, and the production of high-quality disk brake motorcycles.

Products Test

- Visual Inspection

- Thickness Measurement

- Runout Test

- Hardness Testing

- Thermal Performance Testing

- Friction Coefficient Testing

- Durability Testing

Related products

-

Bajaj Platina Disc Brake

$642,607,957.00 -

Honda Shine Disc Brake

-

Front Motorcycle Brake Discs Rotor Yamaha MT 03

-

Kawasaki Ninja 250R Brake Rotors

-

Aftermarket Motorcycle Brake Rotors For Kawasaki Klr650

-

Floating Motorcycle Rear Brake Rotor Disc For Hyosung

-

Best Price 240mm Off Road Brake Discs Plate for Motorcycle

-

Harley Davidson 290mm Front Motorcycle Brake Discs Rotors for XR1200 XR1200X

30,000-70,000 miles depending on the factors.

As often as they need it. On some bikes it was almost every year for pads and around every five years for rotors on the bikes I had that long.