Best Custom Sprockets

- One-Stop Purchasing

- Support Customization

Custom ATV/UTV Sprockets Leading Manufacturer

MPM Company is a leading manufacturer of motorcycle parts, including sprockets, chains, etc. We focus on details to ensure high quality, and can customize motorcycle parts in one stop. Our product quality and convenience have been recognized by the local and international markets under the “MPM” brand.

Custom Motorcycle Sprockets

Customization options

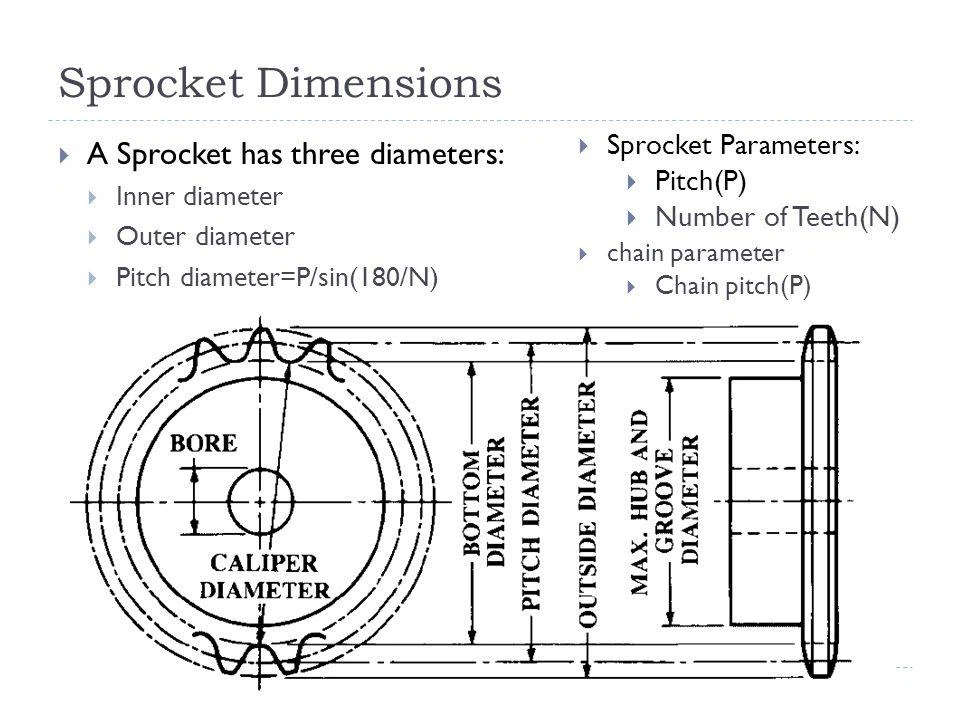

- Dimensions

- Logo

- Package

The process of customizing

1.Determine requirements

Provide specific requirements for sprockets, including size, material, number of teeth, tooth shape, heat treatment requirements, etc.

2.Sign a contract

Both parties need to sign a customized contract to clarify product specifications, quality, price, delivery date and other terms.

3.Custom production

MPM carries out the design and manufacture of sprockets.

Quality inspection: After production is completed, quality inspection is carried out to ensure that the quality of the sprocket meets the requirements.

4.Delivery and after-sales

After passing the inspection, the sprocket will be delivered to the customer and corresponding after-sales service will be provided.

Common Types of Motorcycle Sprocket Materials

Steel Sprockets

Steel sprockets are suitable for a variety of motorcycle types, especially those that are required to carry heavy loads, undergo frequent off-road driving, or are used in harsh environments. Their high strength and wear resistance make them a durable and reliable choice. However, for motorcycle users seeking extreme lightweight and high performance, they may be more inclined to choose sprockets made of aluminum or other high-performance materials.

Steel sprockets are preferred for their high strength, wear resistance and relatively low cost. When choosing a steel sprocket, users need to weigh its weight and susceptibility to corrosion and make a decision based on their specific needs and the environment in which their motorcycle will be used.

Aluminum Sprockets

Aluminum motorcycle sprockets offer significant advantages in lightweight, corrosion resistance and thermal conductivity, but may not be as durable as steel sprockets in high torque and shock environments. Some aluminum sprockets use heat treatment processes and aluminum alloy materials to improve their strength and durability.

At the same time, some aluminum sprockets are also designed with sludge discharge grooves and oxide layers to quickly discharge sludge and enhance corrosion resistance.

Titanium Sprockets

Titanium alloy sprockets are most suitable for motorcycle users who pursue extreme lightweight, high strength and excellent corrosion resistance. They are particularly popular in high-performance racing cars, sportbikes, and motorcycles that need to withstand extreme driving conditions. However, due to the higher cost, users need to weigh its performance advantages against price factors to make a decision.

How to choose a sprocket combination?

How to Choose the Right Sprocket Size

Choosing the right motorcycle sprocket size is crucial for optimal gearing and performance. The sprocket size, along with the chain and rear sprocket, determines the overall gear ratio, which affects acceleration, top speed, and fuel economy.

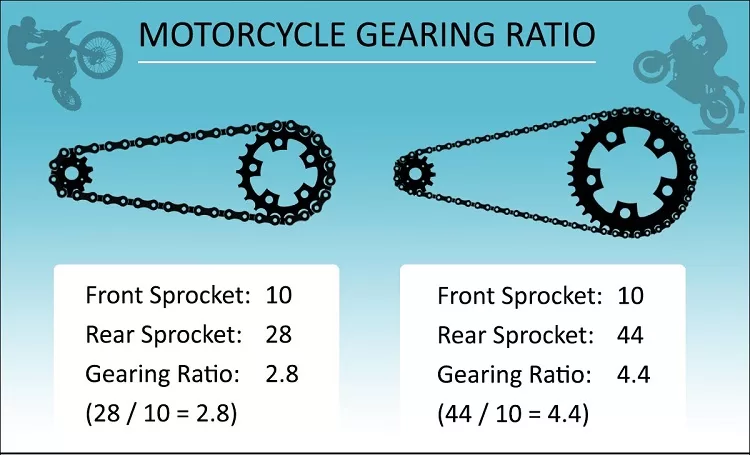

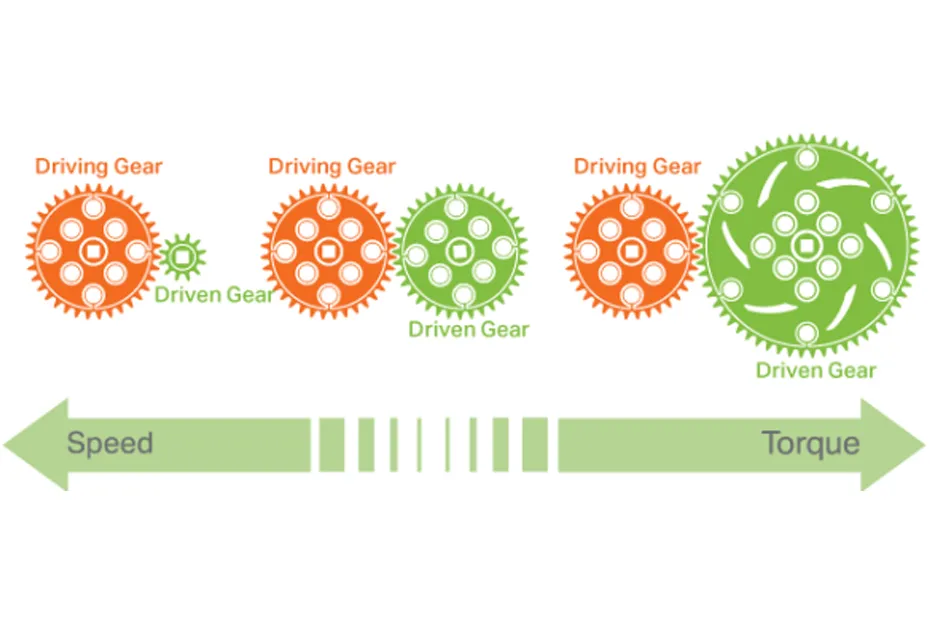

1.Understand Gear Ratios

The gear ratio is the relationship between the front and rear sprocket sizes. A higher gear ratio results in faster acceleration but lower top speed. A lower gear ratio produces slower acceleration but higher top speed. If you frequently ride in hilly or mountainous areas, a lower gear ratio may be beneficial for better climbing ability. If you prefer highway riding or racing, a higher gear ratio may suit your needs for faster acceleration.

2.Consider Your Riding Style

Your riding style should influence your sprocket choice. Aggressive riders who like to accelerate quickly may prefer a larger front sprocket. Riders who prefer a more relaxed pace and better fuel economy may opt for a smaller front sprocket.

3.Evaluate Your Current Sprockets

If you’re replacing worn-out sprockets, measure the current sizes to ensure you get the correct replacements. Note the number of teeth on both the front and rear sprockets.

4.Consider Chain Compatibility

When changing sprocket sizes, make sure your chain is compatible with the new sprockets.

How Teeth Count Affects Performance

The number of teeth on a motorcycle sprocket directly affects the gear ratio and, consequently, the performance characteristics of the motorcycle.

- Gear Ratio and Acceleration

A higher gear ratio results in more acceleration because it creates a shorter distance for the chain to travel, which means faster engagement of the gears.

- Top Speed and Cruising

A lower gear ratio results in a higher top speed because it creates a longer distance for the chain to travel. This ratio is beneficial for highway cruising or when you need to maintain a consistent speed for long periods.

- Engine Load and Fuel Economy

A smaller front sprocket with more teeth places more load on the engine, which requires more fuel to maintain the same speed. Conversely, a larger front sprocket with fewer teeth reduces engine load, potentially improving fuel economy.

- Chain Tension and Sprocket Wear

The teeth count on the sprockets also affects chain tension. If the teeth count is too high or too low, it can lead to improper chain tension, which can cause premature wear on the sprockets and chain.

- Handling and Braking

A higher gear ratio provides more engine braking, which can assist in slowing down the motorcycle, especially when descending hills. Conversely, a lower gear ratio may require more braking effort.

Custom sprockets Recommendations For Your Business

-

Front rear sprocket set for Yamaha Banshee 350 YFZ350

-

ATV rear sprocket chains for Polaris Trail Blazer 330

-

ATV sprocket for Honda TRX400EX TRX400X TRX250R

-

ATV chain sprocket kit 49cc for Suzuki LT50 ALT50 LTA50

-

ATV aluminium rear sprocket for Honda TRX 250 300 400 450

-

Sprocket for Yamaha YFM 700 250 350 Raptor

-

ATV rear sprocket for KTM 450 505 525 XC SX

-

Rear Sprocket for Yamaha YFS200 YFM350 YFM660 YFZ350 YTZ250

To get more speed on your motocross bike, you might consider changing the sprocket ratio. Increasing the rear sprocket size or decreasing the front sprocket size will result in a higher sprocket ratio, which can provide a higher top speed. This setup is often referred to as “higher gearing” or “higher gearing”

By increasing the sprocket ratio, you sacrifice some low-end power and acceleration in exchange for a higher top speed. The engine will have to work harder to reach the same acceleration as before, but once it reaches higher speeds, the taller gearing allows for a greater top speed potential.

It is important to note that changing the sprocket ratio simply to increase speed may not work in all driving conditions. Consider factors such as the terrain you ride on, your riding style and the power characteristics of your trail bike. If you primarily ride on tight and technical off-road trails where quick acceleration is required, a more balanced sprocket ratio may be preferable.

A bigger rear sprocket/ smaller front sprocket will give you an increase in acceleration but decrease your top speed. A smaller rear sprocket/bigger front sprocket will reduce you acceleration but increase the top speed.

It is important to note that changing the sprocket ratio simply to increase speed may not work under all driving conditions. Consider factors such as the terrain you ride on, your riding style and the power characteristics of your trail bike. If you ride primarily on tight, technical trails that require quick acceleration, the sprocket ratio may be more balanced.

ATV/UTV sprockets are not universal and vary in size, design and mounting configuration. While some ATV/UTV sprockets may have similar specifications and compatibility across different models and brands, it’s important to make sure the rear sprocket you choose is specifically designed for your ATV/UTU make, model, and year. It’s important.

ATV/UTV sprockets are manufactured to fit specific hub patterns and may have variations in bolt hole spacing, offset, and tooth count. These specifications must match ATV/UTV wheel and drive system requirements to ensure proper fit and performance.

To determine the correct rear sprocket for your ATV/UTV, refer to your ATV/UTV owner’s manual, contact the manufacturer, or consult a reputable motocross parts supplier. They will provide you with accurate information on compatible rear sprocket options for your specific ATV/UTV model.

Installing an incompatible rear sprocket may result in improper installation, alignment issues, and possible damage to the sprocket, chain, or other driveline components. It is always recommended to use the correct rear sprocket specifically designed for ATV/UTV to ensure optimal performance, safety and longevity.