Custom motorcycle Connecting Rod & Crankshaft Supplier

MPM’s connecting rods and crankshafts are precision machined from premium materials to ensure strength, durability and performance. These products are widely used by many motorcycle manufacturers, wholesalers and individual riders who have strict requirements on machine performance around the world.

MPM’s products are track and street tested and proven to withstand the harshest conditions and deliver outstanding performance.

MPM is designed and developed using the latest CAD/CAM and CNC machines for precise, consistent machining. It produces high-quality forged and machined steel components. Certified to the ISO/TS 16949:2002 standard, in addition to exporting to the US, Italy, UK, France and Germany, it has also successfully supplied to major automotive OEMs, meeting stringent quality requirements.

In addition to crankshafts and connecting rods, MPM offers a range of other high-performance motorcycle parts, including camshafts, cylinder heads, exhaust systems and more. The company’s products are sold worldwide through a network of distributors and dealers who value the quality and performance of MPM’s products.

If you are looking for a reliable and high-performance crankshaft and connecting rod supplier for your motorcycle project, MPM is a great choice. With over 10 years of industry experience, MPM has the knowledge, expertise and resources to meet your specific needs and deliver an exceptional product that exceeds your expectations.

MPM is a professional manufacturer of CNC aluminum connecting rods and crankshafts.

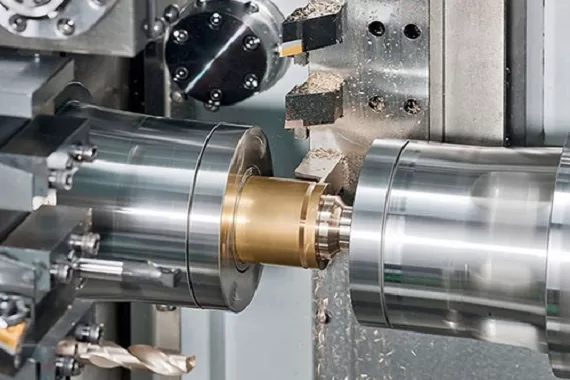

MPM CNC Crankshaft Parts Turning Capability

MPM provides cost-effective and precise CNC manufacturing of motorcycle crankshaft parts including nozzles, fittings, pin connectors, probes and more.

We consistently achieve tight tolerances and ensure superior surface finish and zero defects. Including complex CNC motorcycle crankshaft components.

MPM utilizes through-feed grinding technology to provide a burr-free surface and can process all cylindrical CNC motorcycle crankshaft parts in a variety of diameters.

Our CNC turning services include knurling, grooving, parting, boring and facing, providing comprehensive solutions for a variety of manufacturing needs.

Performance Comparison Of Crankshaft With Different Materials

Crankshaft & Connecting Rod Recommendations For Your Business

-

Crankshaft For Honda Wave125

-

Crankshaft For Honda CB125

-

Crankshaft For Honda CD100

-

Connecting Rod For Suzuki ax100

-

Connecting Rod For Bajaj CT100

-

Connecting Rod For Yamaha DT125

-

Connecting Rod For Bajaj Pulsar 200NS

-

Connecting Rod For Bajaj Pulsar 135

-

Connecting Rod For Honda CD70

-

Connecting Rod For Honda CG200

-

Crankshaft For Bajaj Discover135

-

Crankshaft For Bajaj Boxer BM150

-

Crankshaft For Bajaj Boxer CT100

-

Crankshaft For Suzuki GN125

-

Crankshaft For Bajaj Pulsar 135 LS

-

Crankshaft For Yamaha LC135 Crypton Sniper MX135 RX135

FAQ About Motorcycle Crankshaft & Connecting Rod

The choice of material for a connecting rod depends on various factors such as the application, engine type, performance requirements, and budget. Some common materials used for connecting rods include:

1. Steel: Steel connecting rods are widely used in many production engines and aftermarket performance applications. They offer good strength and durability, making them suitable for a wide range of engine configurations.

2. Aluminum: Aluminum connecting rods are popular in high-performance and racing applications due to their lightweight nature. They can reduce the reciprocating mass in the engine, allowing for higher revving and improved performance. However, they may not be as durable as steel rods and are often more expensive.

3. Titanium: Titanium connecting rods are exceptionally lightweight and offer high strength, making them ideal for high-performance and racing engines. They are often used in top-tier racing applications where weight reduction is critical, but they come with a high price tag.

4. Forged or Billet: Connecting rods can also be made from forged steel or billet aluminum. These processes involve shaping the material under high pressure to create a strong and durable connecting rod.

The best material for a connecting rod depends on the specific requirements of the engine and the intended use of the motorcycle. For custom-built or high-performance applications, consulting with a knowledgeable engine builder or performance specialist MPM can help in determining the best material for the connecting rods.

Connecting rods themselves do not directly add horsepower to an engine. However, they play a crucial role in the overall performance and reliability of the engine, which can indirectly affect horsepower.

The primary function of connecting rods is to transfer the linear motion of the piston to the rotational motion of the crankshaft. Upgraded connecting rods can contribute to the engine’s ability to handle higher levels of power and RPM, which can lead to increased horsepower and torque.

When an engine is modified for higher performance, such as through increased displacement, forced induction, or higher compression ratios, the stock connecting rods may not be able to handle the increased stresses. Upgrading to stronger, more durable connecting rods can allow the engine to reliably produce more power without the risk of component failure.

Additionally, lighter weight connecting rods, such as those made from aluminum or titanium, can reduce the reciprocating mass in the engine, allowing for faster revving and potentially improved horsepower and throttle response.

In summary, while connecting rods themselves do not directly add horsepower, they are a critical component in high-performance engines and can contribute to the engine’s ability to handle increased power and performance modifications.

The choice of the “best” connecting rod depends on the specific requirements of the engine, the intended use of the vehicle, and the budget. Different materials and designs offer various benefits and trade-offs. Here are some considerations for selecting the best connecting rod:

1. Material: Connecting rods are commonly made from steel, aluminum, or titanium. Steel rods are durable and cost-effective, making them suitable for a wide range of applications. Aluminum rods are lightweight and suitable for high-performance and racing applications, while titanium rods offer exceptional strength and reduced weight but come at a higher cost.

2. Design: H-beam and I-beam are the two primary designs for connecting rods. H-beam rods offer high strength and durability, making them suitable for high-stress applications. I-beam rods are lighter and often used in high-revving engines.

3. Application: Consider the specific requirements of the engine, such as power output, RPM range, and intended use (street, track, racing, etc.). The best connecting rod for a high-revving, naturally aspirated engine may differ from the best choice for a turbocharged or supercharged application.

4. Budget: The cost of connecting rods can vary significantly based on the material and design. It’s essential to balance performance requirements with budget constraints.

Ultimately, the best connecting rod is one that is well-matched to the engine’s specific needs, providing the required strength, durability, and performance characteristics. Consulting with experienced engine builders or performance specialists MPM can help in selecting the best connecting rods for a particular application.

The weight of a crankshaft can have an impact on the performance of an engine, but whether a heavier crankshaft is better depends on the specific application and goals of the engine.

In general, a heavier crankshaft can provide more rotational inertia, which can help to smooth out the power delivery and improve low-end torque. This can be beneficial for certain types of engines, such as those used in off-road or heavy-duty applications where low-end power and torque are important.

On the other hand, a lighter crankshaft can reduce rotating mass and inertia, which can lead to improved throttle response, faster revving, and potentially higher top-end power. This can be advantageous for high-performance racing engines or motorcycles where quick acceleration and high RPM operation are desired.

Ultimately, the choice between a heavier or lighter crankshaft depends on the specific requirements of the engine and the intended use of the motorcycle. Custom motorcycle builders and engine tuners often carefully consider the weight and design of the crankshaft to achieve the desired performance characteristics for a particular application.