Custom Harley Davidson Brake Rotors Supplier

MPM is a supplier of motorcycle parts and accessories, as well as a manufacturer and supplier of custom parts for Harley-Davidson in China. We manufacture custom components and accessories for Harley-Davidson motorcycles to meet the specific needs and preferences of Harley-Davidson riders.

Customizing Harley-Davidsons is a popular trend among riders, and MPM offers a range of custom parts such as rotors, exhaust systems, handlebars, seats, and more, allowing riders to personalize their motorcycles.

By sourcing custom parts from MPM, Harley owners in China and elsewhere can get a more personalized riding experience while maintaining the integrity and quality of a Harley-Davidson motorcycle. It is important to note that when choosing custom parts, riders should always ensure that the parts are compatible with the model and specifications of their bike.

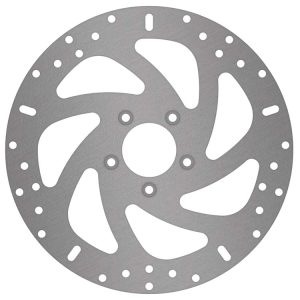

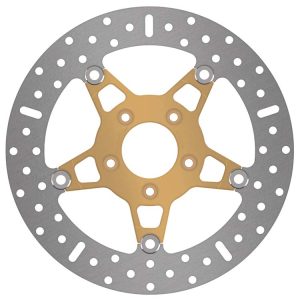

MPM Harley Davidson Brake Rotors Replacement

-

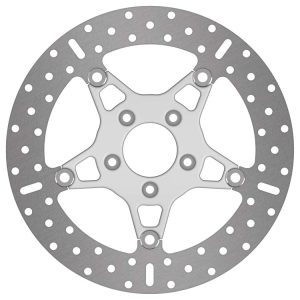

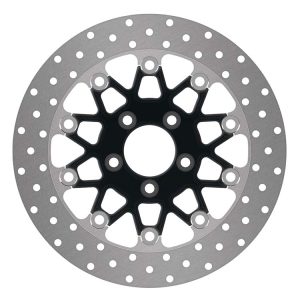

Custom OEM Parts and Accessories for Harley Davidson

-

Harley Davidson 290mm Front Motorcycle Brake Discs Rotors for XR1200 XR1200X

-

Harley Davidson Brake Discs for FLHTCU

-

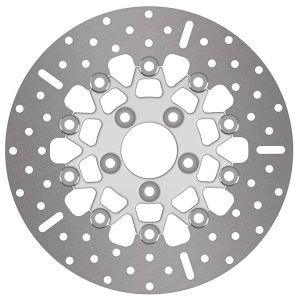

Harley Davidson 300mm Brake Discs Rotors

-

Best brake rotors for harley davidson 300mm

-

Custom brake rotors for harley davidson 300mm

-

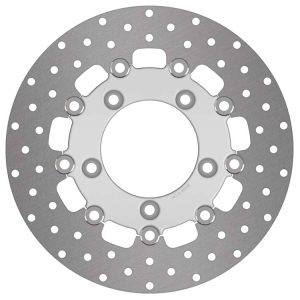

Harley Davidson floating brake rotors 290mm

-

Harley front rotors 300mm

-

Harley brake rotors 300mm

-

Custom harley rotors 260mm

-

Custom harley rotors 290mm front floating

-

Black harley rotors floating 300mm rear

Why Choose MPM Brake Disc Rotors

Raw Materials

Our products are made using the best available materials. Aviation-grade 6061-T6/7075 aluminum alloy for lightweight competition floating brake disc, and stainless steel 420 (2Cr13) for fixed brake disc.

ODM Design

Provide ODM design services for Harley brake discs. We have a deep understanding of every Harley motorcycle enthusiast’s ultimate pursuit of vehicle performance and safety, and create brake discs that meet the requirements.

Production

The essence of a high quality products is in the high precision of manufacturing and the inherent quality of the material. Through accurate machining, ensures products maximum durability and performance.

Surface Treatment

Heat treated and anodized finished to perfection, all products meet or exceed the highest possible quality standards set for the motorcycle industry.

Quality Control

Every Products goes through up to 25 production stages and 10 individual quality control checks before it is ready to leave the factory.Our quality inspection department strictly tests & monitor the entire range at every level of production.They do inspect 100% before delivery.

Products Test

Every batch of our manufactured products are subject to rigorous quality testing, including applicability testing, density testing, product strength and service life testing to ensure that every batch of products leaving our factory is perfect.

Customizing Harley Motorcycle Brake Discs Guide

When customizing your Harley-Davidson motorcycle brake rotors, it’s crucial to make sure you choose the one that best suits your motorcycle and riding needs. This involves several key factors, from material selection and dimensional matching to performance requirements, which all need to be carefully considered. Below is a closer look at these key factors.

1. Material selection

The material of the brake disc directly affects its performance and service life. Common materials include high-performance steel, aluminum alloys, and carbon fiber. High-performance steel has high strength and wear resistance, making it suitable for high-load and high-speed riding situations. Aluminum alloy is relatively light, which helps reduce the weight of the vehicle and improves handling performance. Carbon fiber is known for its excellent lightweight and strength, but its cost is also relatively high. When selecting materials, factors such as performance, weight and budget need to be considered.

2. Size Match

Brake rotors must be sized to match your Harley wheels and braking system. This includes the diameter and thickness of the brake disc as well as the location and size of the mounting holes. Wrong size selection can lead to installation difficulties, poor braking performance and even safety hazards. Therefore, when customizing brake discs, it is important to provide the exact model and year of your motorcycle to ensure that the disc dimensions are a perfect match for your motorcycle.

Generally speaking, the size of Harley motorcycle brake discs will be in the following range:

- Diameter: Typically between 11.5 inches and 13 inches, depending on model and year.

- Thickness: Typically between 0.2 inches and 0.3 inches, also varies by model and year.

11.5" Front Rotor Fitment

11.5" Rear Rotor Fitment

11.8" Front Rotor Fitment

11.8" Rear Rotor Fitment

This guide provides complete fitment information for 11.5″ front and rear rotors and 11.8″ front and rear rotors.For other information, please consult MPM engineers.

3. Performance requirements

Different riding needs have different performance requirements for brake discs. For example, if you regularly drive long distances at high speeds or need to brake frequently, you may want to choose brake discs with higher resistance to heat and wear. For those who mainly ride in the city or on flat roads, they may pay more attention to the smoothness and comfort of the brake disc. So when customizing your brake rotors, be clear about your riding needs so you can choose the rotor that best suits your performance characteristics.

4. Brand and manufacturer selection

Choosing a well-known brand and experienced manufacturer is also key to ensuring the quality of the brake disc. Well-known brands usually have stricter quality control and more advanced production processes, allowing them to provide more reliable and superior-performing brake discs. At the same time, experienced manufacturers can better understand the characteristics and needs of Harley motorcycles, thereby providing you with more suitable customized solutions.

5. Security Considerations

As a key component of the motorcycle braking system, the quality and performance of brake discs are directly related to riding safety. Therefore, when MPM customizes brake discs, it is very important to ensure that the materials, dimensions and performance selected meet safety standards. In addition, professional guidance must be followed during the installation process to ensure that the brake disc is installed correctly and adjusted to its optimal condition.

What are Harley floating rotors?

Harley floating rotors refer to a specific type of brake rotor design used on Harley-Davidson motorcycles. The term “floating” refers to the way the rotor assembly is mounted to the hub.

In a floating rotor setup, the rotor is not firmly fixed to the hub but is allowed to “float” or move slightly within its mount. This movement is usually achieved by using bushings or bearings that allow a small amount of lateral play.

The main advantage of this design is that it helps reduce braking torque and heat transfer to the hub and spokes. When braking, force is primarily absorbed by the rotor itself rather than being transferred to the hub and spokes, which helps maintain the integrity and longevity of these components.

Additionally, floating rotors provide more consistent braking feel and performance because they are less likely to be affected by changes in wheel temperature or thermal expansion.

It’s worth noting that floating rotors are not unique to Harley-Davidson motorcycles and can be found on other makes and models. However, they are a common feature on many Harley models and are often appreciated by riders for their enhanced braking performance and durability.

FAQ About Harley Davidson Brake Rotors

Yes, motorcycle rotors, including those from Harley-Davidson and other brands, can be made in China. China has a large and developed manufacturing base, and MPM is a company specializing in the production of various motorcycle parts including rotors.

These Chinese manufacturers are often capable of producing high-quality rotors that meet or exceed industry standards. They use advanced manufacturing techniques and materials to ensure durability, performance, and safety.

Additionally, many global brands may source their rotors from China but still maintain strict quality control measures to ensure the final product meets their standards. So while the rotors may be made in China, the brand itself usually ensures that they meet its high quality standards.

To sum up, motorcycle rotors can indeed be made domestically, but it is crucial to choose a reliable supplier that can guarantee quality and safety.

Aftermarket motorcycle rotors and OEM (original equipment manufacturer) rotors each have their own advantages and disadvantages, and whether one is “better” than the other depends on specific criteria and the needs of the individual rider.

OEM rotors are designed and manufactured by the motorcycle’s original manufacturer and are custom-made to fit the bike’s original specifications. They are usually the most compatible with the other components of the bike and are usually backed by a manufacturer’s warranty. OEM rotors also tend to have a more consistent fit and finish because they are manufactured to exacting standards.

Aftermarket rotors, on the other hand, offer a wide range of options and customization. Riders can choose from rotors with different materials, finishes and performance characteristics to suit their riding style and needs. Aftermarket rotors can also cost less than OEM rotors, making them a more affordable option for some riders.

However, it’s worth noting that not all aftermarket rotors are created equal. Some may be of lower quality or may not fit the OEM rotor, potentially affecting performance and safety. Therefore, when considering aftermarket rotors, it’s crucial to research and choose reputable brands and suppliers.

All in all, whether aftermarket or OEM rotors are better depends on the specific needs and preferences of the rider. OEM rotors offer a consistent fit and finish and are backed by the manufacturer’s warranty, while aftermarket rotors offer customization and potentially lower costs, but require careful selection to ensure quality and fit.

Yes, Harley-Davidson has manufacturing operations in China. For example, Harley-Davidson cooperates with China’s Qianjiang Motorcycle to produce models such as the Harley-Davidson X350. This motorcycle is manufactured by Qianjiang Factory and sold in the Chinese market. However, it should be noted that although some Harley-Davidson motorcycles are produced in China, the brand’s core technology and design usually remain at Harley-Davidson’s main production base. Therefore, although produced in China, these motorcycles still maintain Harley-Davidson’s consistent high quality and unique style.

In addition, Harley-Davidson also has trading companies in China, such as Harley-Davidson (Shanghai) Trading Co., Ltd., which is responsible for sales and operating activities in the Chinese market.

Generally speaking, Harley-Davidson has production activities in China, but which models are produced in China and the specifics of production may change due to time and market demand. MPM manufactures parts and accessories for Harley-Davidson motorcycles in China.

Harley-Davidson brake rotors are usually made of cast iron or stainless steel. These materials were chosen for their strength, durability and heat resistance, which are critical for effective braking on high-performance motorcycles such as Harley-Davidsons.

Cast iron rotors are common in many motorcycle applications because they dissipate heat well and are relatively cheap to produce. Stainless steel rotors, on the other hand, are known for their corrosion resistance and can provide longer service life in certain environments.

In addition to the materials used, the design and manufacturing process of the brake disc play a vital role in its performance. Harley-Davidson rotors are designed to work in harmony with the bike’s braking system to provide optimal stopping power and feel.

If you have specific questions about your Harley-Davidson brake rotors or are considering an upgrade, you can consult an MPM Motorcycle technician for the best advice.

To determine which motorcycle rotor you have, there are a few steps you can take:

Check the manufacturer information: If you know the make and model of your motorcycle, you can check the manufacturer’s website or owner’s manual. This information should provide details about the original equipment rotors installed on the bike.

Check the rotors: Visually inspect your motorcycle’s rotors. Look for any identifying marks, logos or part numbers that may indicate the rotor manufacturer or type. Sometimes this information is stamped or etched into the rotor itself.

Contact the Dealer or Manufacturer: If you cannot find the information you need through online research or visual inspection, you can contact your motorcycle dealer or manufacturer directly. They should be able to give you detailed information about the rotors installed on your specific bike.

Measure the rotor: As a last resort, you can measure the rotor to determine its size and specifications. This can be done using a tape measure or calipers. Once you have your measurements, you can compare them to rotor specifications available online or through your parts supplier.

Remember, it’s important to use rotors that are compatible with your motorcycle’s make, model, and braking system. If you’re considering replacing your rotors, it’s best to consult a qualified motorcycle technician or parts supplier to ensure you’re getting the correct fit and optimal performance.