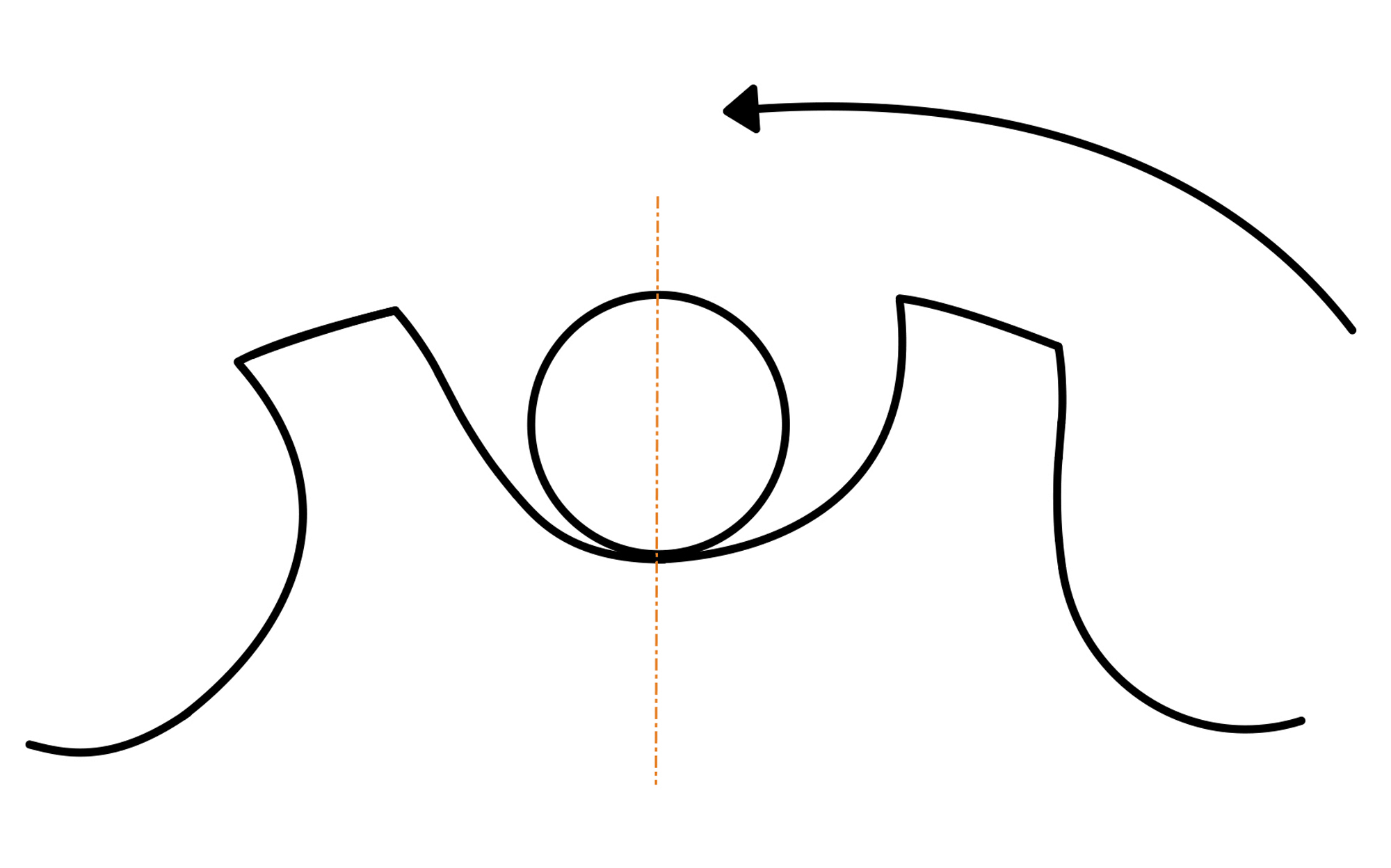

In general, sprockets are made of solid steel 1045 or A3, and the hardness of the teeth can be 45-50. As we noted, when the roller chain elongates, the distance between rollers increases. This phenomenon affects how the chain wraps around the sprocket. When functioning correctly, the roller will fall into the gullet between teeth and then roll off of the driving side of the sprocket tooth. Rollers on an elongated chain do not correctly fall into place, instead impacting the face of the tooth rather than landing in the gullet. This force will begin to wear the teeth down, creating a hooked shape.

The alignment of the sprockets might be the biggest key here. Axial and angular alignment is critical in getting the chain to run smoothly and efficiently. With offset or unaligned sprockets, side plateson the chain can repeatedly hit the side of the sprocket teeth. The same goes for when the sprocket faces are at different angles from one another. Instead of having the chain roll off of the tooth face, it will disengage at an angle that will exert abnormal forces against the teeth.

Join our mailing list to be the first one to know more new parts release and marketing info. Stay informed!

We will contact you within 1 working day, please pay attention to the email “wholesale@mpm-motorsports.com”

Comments